Introduction to Copperplate Paper Release Paper

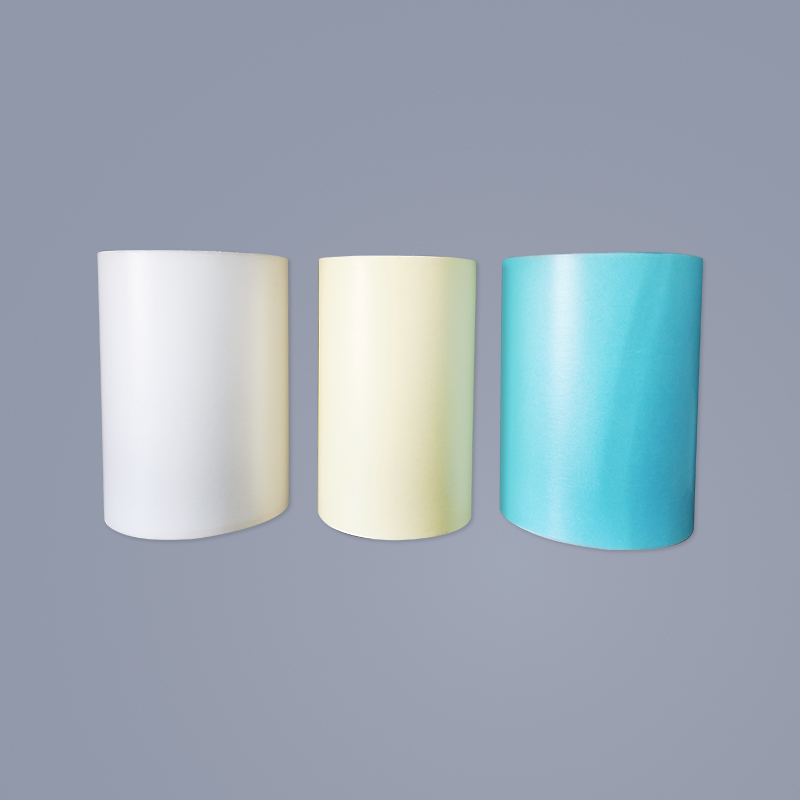

Copperplate Paper Release Paper is a high-quality release liner designed for industrial applications requiring non-stick surfaces. It is used in heat transfer printing, adhesive tape production, label manufacturing, and packaging. Its key feature is a silicone coating that enables smooth separation from adhesives without residue or damage.

- Thickness range: 70-150 gsm (grams per square meter)

- Silicone coating weight: 2-10 g/m²

- Typical width: 500-1500 mm

- Core diameter: 76 mm standard

Coating Structure of Copperplate Paper Release Paper

Base Paper Composition

The base paper provides mechanical strength, flexibility, and dimensional stability. It is usually made from high-quality virgin wood pulp or recycled fibers. The choice of base affects the paper's stiffness, tensile strength, and printability.

- Material: Virgin wood pulp or recycled pulp

- Grammage: 60-120 gsm

- Tensile strength: 25-45 N/15mm (MD), 12-25 N/15mm (CD)

- Moisture content: 4-6%

Silicone Coating Layer

The silicone layer is crucial for the release property. Its thickness, formulation, and curing method determine the release force and temperature resistance.

- Coating thickness: 0.5-3 μm

- Release force: 15-120 g/inch

- Heat resistance: up to 200°C for short duration

- Coating type: cross-linked polydimethylsiloxane (PDMS)

Additional Functional Coatings

Additional layers can improve moisture resistance, anti-static behavior, or heat durability, tailored for specific applications.

- Anti-static coating: surface resistivity 10^9-10^12 ohms

- Moisture barrier: WVTR (Water Vapor Transmission Rate) 1-5 g/m²/day

- Anti-blocking agent: ensures smooth unwinding of paper rolls

Physical Properties of Copperplate Paper Release Paper

Surface Smoothness and Gloss

The paper’s smoothness and gloss are critical for high-quality printing and precise heat transfer applications.

- Surface roughness (Ra): 0.8-1.5 μm

- Gloss (60°): 25-55 GU

- Print compatibility: suitable for flexography and offset printing

Tensile Strength and Durability

Strong base paper and proper silicone coating enhance durability, minimizing tearing and deformation during processing.

- MD tensile strength: 30-45 N/15mm

- CD tensile strength: 15-25 N/15mm

- Elongation: 2-5%

Dimensional Stability

Copperplate Paper Release Paper maintains size and shape under different environmental conditions, ensuring consistent release performance.

- Moisture expansion: <0.2%

- Temperature tolerance: -10°C to 200°C

- Curl: <2 mm per 500 mm length

Applications of Copperplate Paper Release Paper

Heat Transfer Printing

Used as a carrier for heat transfer designs onto fabrics or plastics. Non-stick surface ensures clean transfer without residue.

- Heat resistance: up to 180°C

- Release force: 20-80 g/inch

- Common substrates: textiles, plastics

Labeling and Packaging

Provides a stable backing for adhesive labels, enabling easy peeling and high printing quality.

- Surface gloss: 30-50 GU

- Paper thickness: 80-120 gsm

- Release force: 15-90 g/inch

Adhesive Tape Production

Acts as the backing to prevent tape from sticking to itself, maintaining adhesive performance during storage.

- Coating thickness: 1-3 μm

- Release force: 25-100 g/inch

- Paper width: customizable, 500-1500 mm

Environmental Considerations

Use of Sustainable Materials

Eco-friendly production focuses on recycled fibers, renewable materials, and reduced chemical usage.

- Recycled content: 30-100%

- Biodegradable coatings: silicone or plant-based alternatives

- Reduced VOC emissions during production

Recyclability and Disposal

Proper disposal and recycling help minimize environmental impact.

- Recyclable with standard paper waste streams if coating is water-based or biodegradable

- Incinerable for energy recovery without harmful residue

- Composting possible with fully biodegradable versions

Conclusion

Copperplate Paper Release Paper is a versatile material combining a strong base paper with a functional silicone coating. Its detailed physical properties, dimensional stability, and specialized coatings make it ideal for heat transfer printing, labeling, packaging, and adhesive applications, while sustainable production options enhance environmental benefits.

Frequently Asked Questions (FAQ)

1. What are the main advantages of Copperplate Paper Release Paper?

Copperplate Paper Release Paper offers excellent release properties, high dimensional stability, and superior surface smoothness. It is suitable for heat transfer printing, labeling, packaging, and adhesive tape production. The paper’s silicone coating ensures clean separation without residue, making it ideal for industrial applications.

2. Can Copperplate Paper Release Paper be customized for specific industrial needs?

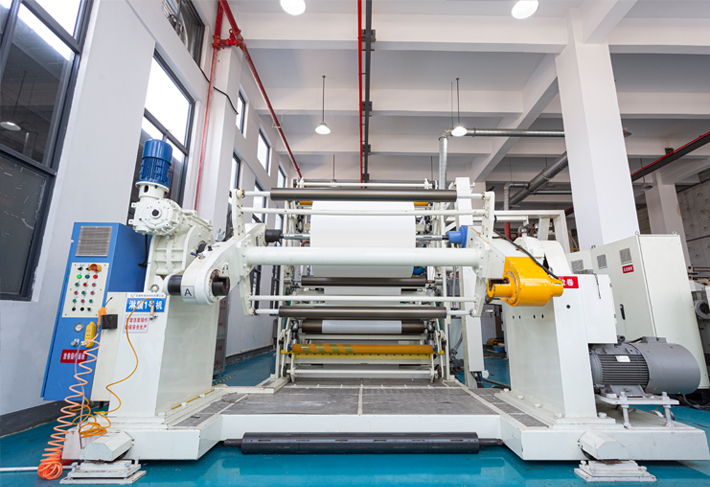

Yes, the base paper, silicone coating thickness, release force, and additional functional layers can be tailored according to application requirements. Anhui Hengbo New Material Co., Ltd. provides customization options for industries such as printing, silk screen printing, pad printing, electronics, lamination, medical plaster paper, adhesive products, and more. The company adheres to ISO9001 certification standards and emphasizes customer-oriented, thoughtful service.

3. How does Anhui Hengbo New Material Co., Ltd. ensure product quality and environmental responsibility?

Anhui Hengbo New Material Co., Ltd., established in 2017, focuses on high-quality PET polyester film, PET release film, and protective film. Products are widely used across multiple industries, including electronics, printing, and medical applications. The company follows rigorous safety production standards and ISO9001 international certification. Sustainable production practices, use of recyclable materials, and eco-friendly coatings are integrated to minimize environmental impact while maintaining superior product performance.