- 1 Raising the Bar: Quantifying surface energy of PET film in dynes

- 2 Dry Surface Activation: Corona treatment optimization for PET film

- 3 Wet Chemical Enhancement: Primer coating effectiveness on PET adhesion

- 4 Application Focus: Enhancing ink adhesion on PET film material and Coating Uniformity

- 5 Anhui Hengbo New Material Co., Ltd.: Focused on PET Film Solutions

- 6 Frequently Asked Questions (FAQ)

- 6.1 1. Why is the surface energy of raw PET film material typically too low for coating?

- 6.2 2. How is the surface treatment quality primarily quantified?

- 6.3 3. What is the key advantage of Plasma surface activation of polyester film over **Corona treatment optimization for PET film**?

- 6.4 4. What is the minimum required surface energy for Enhancing ink adhesion on PET film material in industrial printing?

- 6.5 5. What is the technical function of a primer coating in relation to PET film material?

The **PET film material** (Polyethylene Terephthalate) is highly valued for its mechanical strength, clarity, and thermal stability. However, its chemically inert, non-polar surface typically possesses low surface energy, leading to poor wetting and weak adhesion of inks, adhesives, and functional coatings (such as anti-static or hard coats). To successfully integrate **PET film material** into applications like membrane switches, flexible circuits, and reflective materials, specialized surface modification techniques are essential to increase surface energy and ensure long-term bonding integrity. This begins with rigorous quantification methods, like Quantifying surface energy of PET film in dynes.

Raising the Bar: Quantifying surface energy of PET film in dynes

Surface energy measurement is the foundation of surface treatment quality control, enabling objective assessment of the treatment's success.

Contact Angle Measurement: The Primary Quantification Method

- **Principle:** Surface energy is inversely proportional to the contact angle formed by a test liquid (e.g., distilled water, diiodomethane) on the film surface. A lower contact angle indicates higher surface energy and better wettability.

- **Unit:** Surface energy is measured in dynes per centimeter (dynes/cm). This is the key metric for Quantifying surface energy of PET film in dynes and predicting coating performance.

Target Surface Energy Levels for Industrial Adhesion

An untreated **PET film material** typically exhibits a surface energy below 40 dynes/cm, which is insufficient for most industrial coatings. Post-treatment, the target surface energy must be raised significantly higher to achieve reliable adhesion.

Untreated vs. Treated PET Film Surface Energy Table

| Treatment Status | Surface Energy Range (dynes/cm) | Coating Adhesion Suitability |

|---|---|---|

| Untreated Film | 38 – 42 dynes/cm | Poor (High risk of peeling and delamination). |

| Corona Treated (Optimized) | 50 – 58 dynes/cm | Good (Sufficient for most inks and basic adhesives). |

| Plasma/Primer Treated | 58 – 72 dynes/cm | Excellent (Required for specialized hard coats and high-strength lamination). |

Dry Surface Activation: Corona treatment optimization for PET film

Dry surface activation methods utilize electrical discharge or plasma to modify the film's chemical structure.

Mechanism and Limitations of Corona Treatment

- **Mechanism:** Corona treatment bombards the **PET film material** surface with high-voltage, high-frequency electrical discharge, creating reactive species (radicals) that oxidize the surface, incorporating polar groups (like C=O and C-OH). This is the most common process for Corona treatment optimization for PET film.

- **Limitations:** The effect of corona treatment is transient; the elevated surface energy can decay over time (within hours or days), particularly in high-humidity storage conditions.

Plasma surface activation of polyester film: Precision and Permanence

In contrast to corona, Plasma surface activation of polyester film uses a controlled vacuum environment and specific process gases (e.g., oxygen, argon). Plasma treatment provides a more uniform, deeper, and longer-lasting modification of the film surface, achieving a higher surface energy that decays much more slowly than standard corona treatment.

Wet Chemical Enhancement: Primer coating effectiveness on PET adhesion

For applications demanding maximum adhesion and durability, chemical priming is often the solution.

Functionality of Primer Coatings (Chemical vs. Mechanical Bonding)

- **Primer Role:** Primer coatings act as a molecular bridge. They chemically bond to the film surface and present a functional surface (e.g., polyurethane, acrylic) that is highly receptive to the specific topcoat. This maximizes the Primer coating effectiveness on PET adhesion.

Optimizing Primer Chemistry for Specific Coatings

The success of the primer relies on matching its chemistry to the final coating. For instance, acrylic primers are often used before UV-curable hard coats, whereas polyester-based primers may be used to enhance adhesion to certain pressure-sensitive adhesives, leading to superior final product integrity.

Application Focus: Enhancing ink adhesion on PET film material and Coating Uniformity

Achieving consistent quality across wide film rolls is critical for B2B manufacturing.

The Necessity of Treatment Uniformity for Wide Web Processing

- **Uniformity:** In wide web processing (e.g., 1000mm film), any variation in the corona or plasma treatment level (called "patchiness") leads to inconsistent adhesion, which is catastrophic for processes like silk screenprinting and lamination. Strict process control is essential for Enhancing ink adhesion on PET film material uniformly.

Validation of Long-Term Adhesion (Peel and Cross-Hatch Testing)

The final confirmation of surface modification is done through destructive testing: Peel strength testing (ASTM D903) quantifies the adhesion force, while Cross-Hatch testing (ASTM D3359) assesses the resistance of the coating to separation from the film surface, providing critical validation of the entire surface modification process.

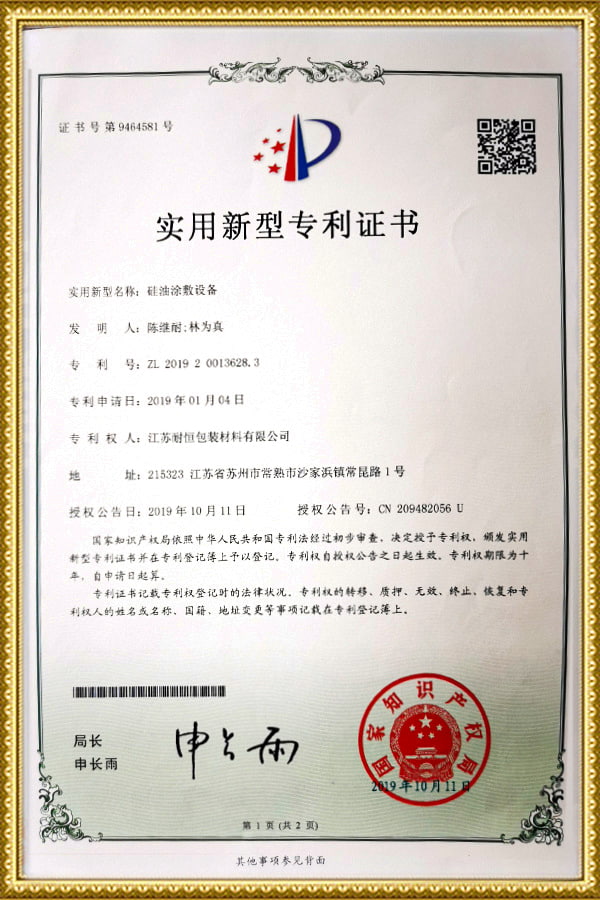

Anhui Hengbo New Material Co., Ltd.: Focused on PET Film Solutions

Anhui Hengbo New Material Co., Ltd., established in 2017, is a major manufacturer specializing in **PET film material**, PET release film, and protective film. Our products are foundational to industries ranging from electronics and flexible circuits to printing and die-cutting. We adhere to stringent quality standards, evidenced by our ISO9001 certification. Our goal is to provide customized solutions, particularly in surface modification, ensuring our base **PET film material** is perfectly prepared for specific functional coatings. We leverage our expertise to ensure our films achieve the optimal surface energy required, whether it's for Enhancing ink adhesion on PET film material in printing or maximizing Primer coating effectiveness on PET adhesion for lamination. We are committed to patient inquiry response and providing professional, reasonable quotations based on the principle of customer service.

Frequently Asked Questions (FAQ)

1. Why is the surface energy of raw PET film material typically too low for coating?

Raw PET is a non-polar polymer with an inherently smooth, chemically inert surface, which means it has low surface energy (typically < 40 dynes/cm). Low surface energy causes liquids, like inks or adhesives, to bead up instead of wetting and bonding uniformly.

2. How is the surface treatment quality primarily quantified?

The quality is primarily quantified by measuring the film's surface energy in dynes/cm, usually via the contact angle method. A lower contact angle with a test liquid confirms a higher surface energy.

3. What is the key advantage of Plasma surface activation of polyester film over **Corona treatment optimization for PET film**?

Plasma treatment offers a more stable and permanent increase in surface energy compared to corona treatment. The effect of plasma decays much slower, which is essential for films that require longer storage times before secondary processing.

4. What is the minimum required surface energy for Enhancing ink adhesion on PET film material in industrial printing?

For reliable ink adhesion, the surface energy must generally be raised to at least 50 dynes/cm, although critical applications often demand 56 dynes/cm or higher to ensure long-term bonding and prevent ink rub-off.

5. What is the technical function of a primer coating in relation to PET film material?

The primer acts as a chemical bridge, bonding to the chemically activated PET surface on one side and providing a highly receptive functional group (e.g., hydroxyl or amine) on the other side, specifically tailored for strong adhesion to the final topcoat or adhesive layer.