Introduction to Printable Release Paper

Definition and Purpose

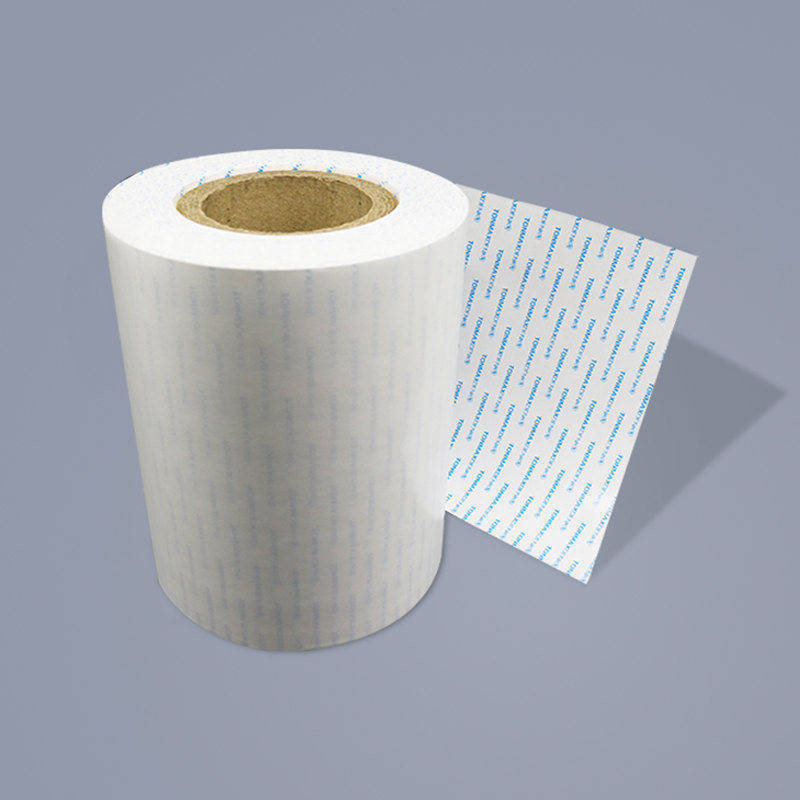

- Printable Release Paper is specially coated paper designed to prevent adhesive transfer during printing and processing.

- It serves as a protective liner in printing, laminating, and electronics industries.

Key Industries and Applications

- Electronics: membrane switches, flexible circuits, circuit boards

- Printing: silk screen printing, pad printing, nameplates

- Adhesives: die-cutting, punching, pressure-sensitive products

- Medical: plaster paper, packaging, protective films

Advantages Over Traditional Papers

- Enhanced durability and chemical resistance

- Consistent release performance

- Customizable thickness and surface properties

Common Materials Used in Printable Release Paper

Glassine Paper

- Smooth, semi-transparent, and resistant to air and water

- Widely used in adhesive liners, food packaging, and printing

PET Polyester Film

- Strong, durable, and chemical resistant

- Common in electronics, lamination, and reflective materials

Silicone Coated Papers

- Provides excellent non-stick release properties

- Superior for adhesive tapes, laminating, and die-cutting

- Comparison Table:

| Material | Release Performance | Durability | Application |

| Glassine | Medium | Moderate | Printing, Adhesive Liners |

| PET Film | High | High | Electronics, Lamination |

| Silicone Coated | Excellent | High | Adhesive Products, Die-Cutting |

Specifications of Printable Release Paper

Thickness and Weight

- Glassine: 35-60 gsm

- PET Film: 12-50 microns

- High-Temperature: up to 80 microns

Surface Treatment

- Silicone coating: excellent release

- High-temperature coating: withstands heat up to 200°C

- Comparison Table:

| Coating Type | Release Property | Temperature Resistance | Typical Use |

| Silicone | Excellent | 120°C | Adhesives, Laminates |

| High-Temperature | Good | 200°C | Heat Printing, Electronics |

Transparency and Color Options

- Transparent: easy alignment in printing and electronics

- Opaque: better for masking and decorative applications

Applications of Printable Release Paper

- Printing and Silk Screen Printing

- Pad Printing and Nameplates

- Membrane Switches and Flexible Circuits

- Adhesive Products and Die-Cutting

- Medical Plasters and Packaging

Choosing the Right Printable Release Paper

- Custom PET Release Film for durability and lamination

- Silicone Coated Release Paper for adhesive separation

- High-Temperature Printable Paper for heat-resistant applications

- Transparent Release Film Sheets for visual alignment in printing

- Printable Release Liner for Adhesives for pressure-sensitive products

FAQ on Printable Release Paper

- Q1: What is Printable Release Paper used for?

A: It is used as a protective liner for adhesives, printing, lamination, and electronic products. - Q2: How do I choose between glassine and PET film?

A: Glassine is ideal for low-cost, lightweight applications, PET film is stronger and chemical-resistant. - Q3: What is the benefit of silicone coating?

A: Provides superior release performance, preventing sticking of adhesives or laminated materials. - Q4: Can Printable Release Paper handle high temperatures?

A: Yes, high-temperature coated variants can withstand up to 200°C. - Q5: Are there transparent options available?

A: Yes, Transparent Release Film Sheets allow easy alignment in printing and electronics.