- 1 1. Thermal Stability of the Silicone Coating and Base Paper

- 2 2. Humidity and Moisture Vapor Transmission Rates (MVTR)

- 3 3. Chemical Interaction and Adhesive Aging

- 4 4. Mechanical Stress and Die-Cutting Precision

- 5 5. Conclusion: Guiding Customers to Success

- 6 Frequently Asked Questions (FAQ)

- 6.1 1. How to store silicone release paper to ensure maximum shelf life?

- 6.2 2. What is the advantage of solventless vs solvent based silicone coating?

- 6.3 3. Why do I need differential release paper applications?

- 6.4 4. Can Anhui Hengbo provide customized double sided release paper for medical use?

- 6.5 5. Is temperature resistant silicone release liners necessary for all electronics?

- 7 Industry References

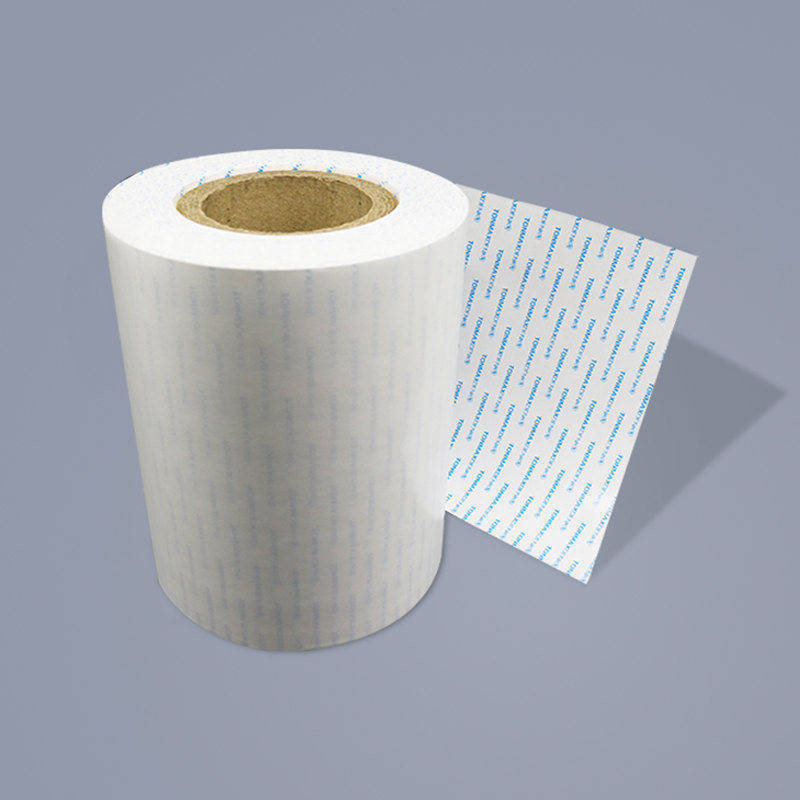

In the precision-driven world of adhesive converting and industrial lamination, the reliability of the release carrier is paramount. The double sided silicone release paper is a specialized substrate coated with silicone on both surfaces, designed to provide a consistent release force for double-sided tapes and membrane switches. Anhui Hengbo New Material Co., Ltd., established in 2017 and ISO9001 certified, stands as a premier manufacturer of PET polyester films and advanced release materials. We specialize in providing customized solutions for flexible circuits, insulating products, and waterproof materials. Understanding how to store silicone release paper and the technical variables influencing its behavior in harsh environments is critical for engineers aiming to prevent adhesive transfer or liner failure. When a double sided silicone release paper is exposed to extreme thermal or hygroscopic stress, its performance is dictated by the synergy between the base paper fibers and the silicone polymer matrix.

1. Thermal Stability of the Silicone Coating and Base Paper

Extreme temperatures can cause significant changes in the mechanical properties of a double sided silicone release paper. High heat may lead to "silicone migration," where the release agent loses its bond with the base paper and contaminates the adhesive. Conversely, temperature resistant silicone release liners are engineered to withstand prolonged thermal exposure without becoming brittle. While glassine-based papers offer excellent heat resistance, Kraft-based papers may undergo dimensional shrinkage if the moisture content is not strictly controlled during production. At Anhui Hengbo, we ensure our thermal stability profiles meet the rigorous demands of the electronics and circuit board industries.

Comparison: High-Temperature Performance by Substrate

Synthetic PET-based liners generally offer higher thermal resistance and dimensional stability than paper-based liners when subjected to temperatures exceeding 150°C.

| Property | Paper-Based Release Liner | PET-Based Release Film |

| Continuous Operating Temp | Up to 120°C (Short term higher) | Up to 180°C (Excellent stability) |

| Dimensional Shrinkage | Moderate (Moisture dependent) | Ultra-Low (Thermal set) |

| Surface Smoothness | Standard (Textured) | Superior (Optical Grade) |

2. Humidity and Moisture Vapor Transmission Rates (MVTR)

Humidity is perhaps the most challenging factor for double sided silicone release paper. Paper is naturally hygroscopic; high humidity causes the cellulose fibers to swell, leading to "curling" or "cockling" of the liner. This distortion can catastrophically affect die-cutting precision. Using a solventless vs solvent based silicone coating affects how well the paper is sealed. Solventless systems often provide a more uniform barrier, reducing the MVTR. In environments where humidity fluctuates, engineers must prioritize differential release paper applications to ensure that one side remains manageable even if the moisture levels change the liner's tension.

Comparison: Humidity Impact on Coated vs. Uncoated Sides

Silicone coatings act as a moisture retardant; however, double-sided coatings provide a more balanced moisture barrier compared to single-sided alternatives.

| Condition | Low Humidity (<20% RH) | High Humidity (>80% RH) |

| Substrate Reaction | Static buildup and brittleness | Fiber swelling and loss of stiffness |

| Release Force Impact | Increases (Adhesive hardens) | Decreases (Adhesive softens/potential "ghosting") |

| Structural Integrity | Remains flat | Risk of curling if tension is unbalanced |

3. Chemical Interaction and Adhesive Aging

Under extreme conditions, the chemical interaction between the adhesive and the double sided silicone release paper accelerates. High temperature and humidity can trigger "locking," where the adhesive bonds permanently to the release liner. This is often caused by incomplete curing of the silicone or the presence of residual catalysts. For industries like medicine (plaster paper) and reflective materials, Anhui Hengbo New Material Co., Ltd. utilizes advanced curing technology to ensure a stable release force. Our customized double sided release paper is formulated to maintain a "clean" release, ensuring no silicone transfer occurs onto the adhesive surface, which is vital for the electronics and die-cutting industries.

4. Mechanical Stress and Die-Cutting Precision

When double sided silicone release paper is used in automated die-cutting, the tensile strength must remain constant regardless of external conditions. Humidity-induced softening can lead to "slugs" or poor edge quality during the punching process. Anhui Hengbo provides high-tensile PET release film and paper solutions that resist elongation under load. By adhering to our people-oriented philosophy and safety production standards, we guide our customers to select the correct thickness and density to ensure that extreme weather does not compromise the manufacturing throughput of membrane switches or flexible circuits.

Technical Engineering Checkpoints:

- Cure Level: Ensure >95% cure to prevent silicone migration in heat.

- Basis Weight: Higher GSM paper provides better structural resistance to humidity.

- Differential Release: Specifying a "tight" side and an "easy" side for complex lamination.

- Barrier Coating: Utilizing PE-lamination for maximum moisture protection.

5. Conclusion: Guiding Customers to Success

The performance of double sided silicone release paper is a delicate balance of material science and environmental control. Factors such as substrate choice, silicone curing integrity, and MVTR play decisive roles in how a liner survives extreme heat or moisture. Anhui Hengbo New Material Co., Ltd. remains committed to providing professional quotations and customized solutions that address these engineering challenges. Whether your application is in reflective materials, waterproof products, or high-tech electronics, our goal is to provide the thoughtfully designed materials you need to ensure your project's success.

Frequently Asked Questions (FAQ)

1. How to store silicone release paper to ensure maximum shelf life?

Silicone release paper should be stored in a climate-controlled environment, ideally at 20-25°C and 50% relative humidity. Keep the rolls in their original moisture-proof packaging until they are ready for use to prevent curling caused by environmental fluctuations.

2. What is the advantage of solventless vs solvent based silicone coating?

Solventless coatings are more environmentally friendly and often provide better cost-efficiency for mass production. Solvent-based coatings, however, are sometimes preferred for very low release forces and high-speed applications where surface smoothness is the absolute priority.

3. Why do I need differential release paper applications?

Differential release allows you to apply a double-sided adhesive to the liner and ensure that when the user peels it, the adhesive stays on the intended side. This is crucial for tapes and decorative nameplates.

4. Can Anhui Hengbo provide customized double sided release paper for medical use?

Yes. Our products are widely used in the medicine (plaster paper) industry. We ensure our release materials are manufactured under strict ISO9001 standards to meet the cleanliness and performance requirements of medical adhesive products.

5. Is temperature resistant silicone release liners necessary for all electronics?

If the production process involves heat-curing or lamination at high temperatures (above 100°C), temperature-resistant liners are essential to prevent the liner from warping or the silicone from migrating into the delicate electronic circuits.

Industry References

- FINAT Technical Handbook: Test Methods for Self-Adhesive Materials.

- ISO 9001:2015 - Quality Management Systems Standards.

- PSTC (Pressure Sensitive Tape Council): Glossary of Terms and Test Methods.

- Anhui Hengbo New Material Co., Ltd. Internal Laboratory Test Reports: Thermal and Hygroscopic Analysis (2025).