- 1 1. The Technical Requirements for Medical Grade Release Liners

- 2 2. PET Release Film vs. Glassine Release Paper Roll

- 3 3. Optimizing Release Force for Patient Comfort

- 4 4. Specialized Applications: Plasters and Die-Cutting

- 5 Conclusion: Custom Solutions for a Healthier Future

- 6 Frequently Asked Questions (FAQ)

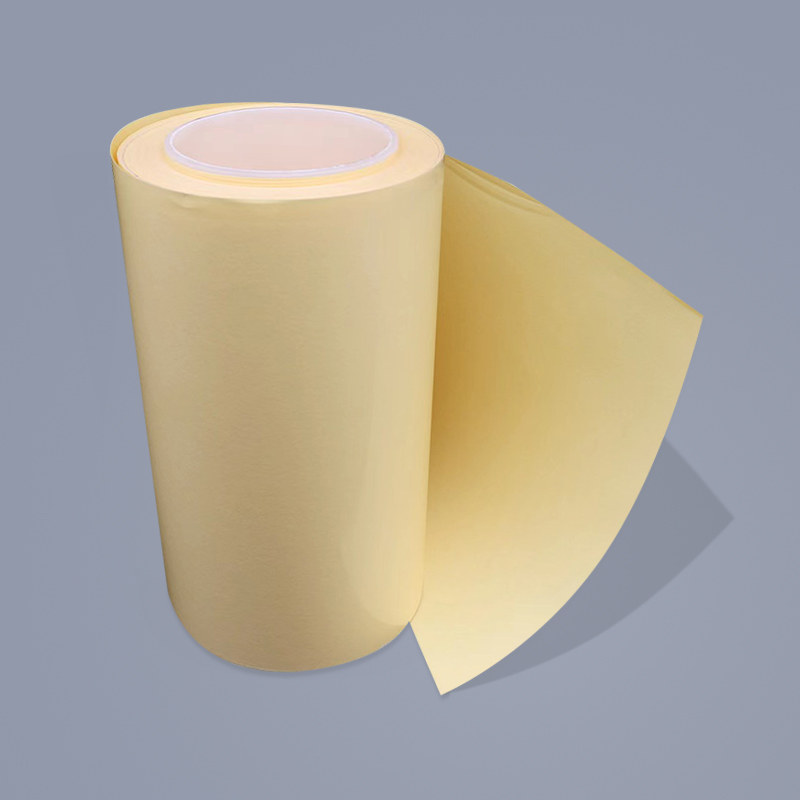

Selecting the appropriate release paper roll for medical applications is a task that requires a deep understanding of material science and biocompatibility. In the medical field, pressure-sensitive adhesives (PSAs) used for wound dressings, transdermal patches, and surgical tapes demand a liner that offers consistent release force and zero contamination. Anhui Hengbo New Material Co., Ltd., established in 2017, has become a leading specialist in the manufacturing of PET polyester film and PET release film. With our ISO9001 certification and a philosophy rooted in providing customized solutions, we serve the pharmaceutical and electronics industries by ensuring our materials meet the highest safety and production standards.

1. The Technical Requirements for Medical Grade Release Liners

Medical-grade adhesives are often more sensitive than industrial variants. A high-quality release paper roll must be manufactured in a controlled environment to prevent particulate contamination. For applications like plaster paper or medicine patches, the liner must exhibit high chemical stability to ensure it does not react with the active pharmaceutical ingredients (APIs). While standard clay-coated papers are common in logistics, medical devices frequently require a silicone coated release paper for medical use to ensure an ultra-smooth, hypoallergenic surface.

Compared to standard industrial liners, medical liners must prioritize "low extractables" to prevent any chemical migration into the adhesive layer, which could cause skin irritation.

| Feature | Industrial Release Paper | Medical Grade Release Liner |

| Cleanliness Level | General Industrial | Cleanroom Grade / ISO Class 7-8 |

| Coating Type | Standard Silicone | Solvent-free or Controlled-extraction Silicone |

| Biocompatibility | Not Required | ISO 10993 Compliance Often Necessary |

2. PET Release Film vs. Glassine Release Paper Roll

In the medical industry, the two primary substrates used are PET film and Glassine paper. A PET release film for wound dressing is often preferred for transparent dressings because it offers superior dimensional stability and clarity, allowing for visual inspection of the adhesive layer. Conversely, a glassine release paper roll is highly valued for its heat resistance and high density, making it ideal for high-speed die-cutting processes. At Anhui Hengbo, we find that B2B customers often choose PET-based solutions when precision and moisture resistance are the top priorities.

While PET film provides a smoother surface finish, Glassine paper offers better breathability and environmental degradability for certain disposable applications.

| Substrate | PET Polyester Film Liner | Glassine Paper Liner |

| Transparency | Excellent / Crystal Clear | Semi-transparent to Opaque |

| Die-cutting Precision | Very High (No fiber tear) | High (Clean snap) |

| Moisture Sensitivity | Waterproof / Non-absorbent | Sensitive to humidity fluctuations |

Source: FEFCO Technical Report 2024 - Material Standards for Specialized Paper Substrates

3. Optimizing Release Force for Patient Comfort

The "release force" is the amount of energy required to peel the adhesive from the release paper roll. In medical settings, this force must be extremely consistent to ensure that a nurse or patient can easily remove the liner without damaging the delicate thin-film dressing underneath. For wholesale medical grade release liners, we utilize advanced coating technology to customize the release profile—from "easy release" for large bandages to "tight release" for small, intricate die-cut parts.

Recent market statistics from 2024 indicate a 12% increase in the demand for solvent-free silicone coatings in the medical sector, driven by stricter environmental regulations and a focus on patient skin safety. Furthermore, technical breakthroughs in UV-cured silicone have allowed for the production of liners with even lower migration levels than traditional thermal-cured systems.

Source: FDA - Current Good Manufacturing Practice (CGMP) for Medical Device Materials 2025

4. Specialized Applications: Plasters and Die-Cutting

Beyond simple bandages, the double sided release paper for adhesive products is essential for double-coated medical tapes used in mounting sensors or wearable devices. These require a differential release, where one side peels more easily than the other. Anhui Hengbo's production lines are equipped to handle these complex requirements, providing die-cutting and punching processing services that ensure the edges are clean and free of adhesive "ooze," which is vital for sterile medical packaging.

Conclusion: Custom Solutions for a Healthier Future

The best release paper roll for medical-grade PSAs is ultimately the one that balances technical performance with patient safety. Whether your application requires the clarity of a PET release film or the robustness of a glassine liner, Anhui Hengbo New Material Co., Ltd. is committed to guiding our customers toward success with professional quotations and patient service. Our goal is to provide the market with customized solutions that meet the diverse and rigorous demands of the global healthcare industry.

Frequently Asked Questions (FAQ)

- Can PET release film be sterilized?

Yes, PET-based liners are generally compatible with Ethylene Oxide (EtO) and Gamma sterilization, which are standard for medical devices. - What is the typical shelf life of a medical release paper roll?

Under proper storage conditions (20°C and 50% humidity), most silicone-coated liners maintain stable release properties for 12 to 24 months. - Why is silicone used as the release agent?

Silicone has a very low surface energy, which prevents the medical-grade adhesive from forming a permanent bond, allowing for a smooth peel. - Do you offer double sided release paper for adhesive products in custom widths?

Yes, as a specialized manufacturer, we provide customized widths and lengths to suit specific die-cutting and punching processing machinery. - Is your PET release film compliant with food and medical standards?

Our company is ISO9001 certified, and our PET products are widely used in medical (plaster paper) and electronic industries, adhering to strict quality control protocols.