- 1 Understanding Differential Release Levels in Multi-Layer Adhesives

- 2 Preventing Adhesive Migration through Surface Energy Calibration

- 3 Material Science and Stability in Industrial Processing

- 4 Precision Die-Cutting and Punching: The Professional Perspective

- 5 Conclusion: Anhui Hengbo's Commitment to Material Excellence

- 6 Frequently Asked Questions (FAQ)

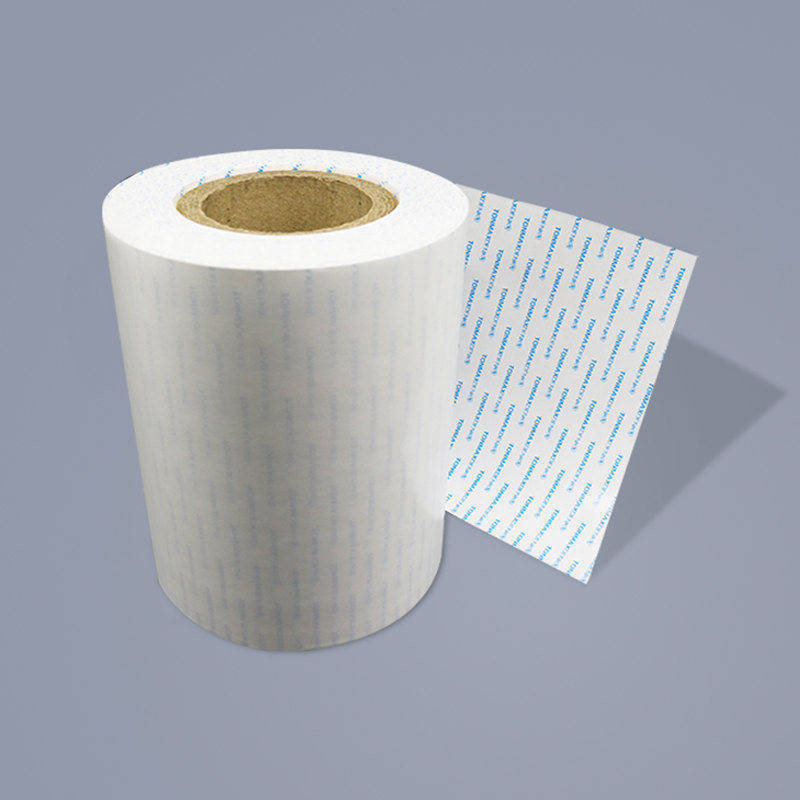

In the specialized world of adhesive conversion and die-cutting, the performance of a double sided silicone release paper is determined by its ability to manage two different adhesive interfaces simultaneously. Precision die-cutting requires more than just protection; it demands "differential release"—a technical configuration where one side of the liner releases more easily than the other. This mechanical discrepancy is vital for preventing adhesive migration and ensuring clean separation during complex punching processes. Anhui Hengbo New Material Co., Ltd., established in 2017, focuses on providing these customized solutions through advanced PET polyester film and release film technology, serving high-precision industries like flexible circuits, membrane switches, and medical lamination.

Understanding Differential Release Levels in Multi-Layer Adhesives

Differential release is achieved by varying the silicone coating density or the curing method on each side of the substrate. This ensures that when a tape or adhesive is unrolled or processed, it remains firmly attached to the "tight" side while releasing cleanly from the "easy" side. According to the 2024-2025 Global Silicone Release Liner Market report, the demand for high-performance differential liners in the electronics sector has grown by 8.5% due to the miniaturization of circuit boards.

The Mechanics of differential release double sided silicone paper

By using differential release double sided silicone paper, engineers can control the peel force ratio (typically 1:2 or 1:3). This prevents "adhesive ghosting" or migration, where the adhesive partially transfers to the wrong side of the liner during the die-cutting stroke. This control is essential for maintaining the integrity of insulating products and nameplates.

Preventing Adhesive Migration through Surface Energy Calibration

Adhesive migration often occurs when the surface energy of the release liner is too close to the surface tension of the adhesive. To mitigate this, high-precision manufacturing involves the use of custom double sided release liners for adhesives that are specifically matched to the chemical composition of the adhesive—whether it be acrylic, rubber-based, or silicone-based.

Solving Complexity with custom double sided release liners for adhesives

When dealing with sensitive materials like laser anti-counterfeiting films or medical grade plasters, the release liner must be inert. A customized solution ensures that the silicone does not "bleed" into the adhesive, which would otherwise compromise the bond strength once the product is applied to its final destination.

Comparison: Symmetrical vs. Differential Release Forces

In a symmetrical setup, both sides provide equal resistance, which often leads to processing errors in automated lines. Differential liners, however, provide a "staged" release that facilitates high-speed conversion without delamination.

| Feature | Symmetrical Release Liner | Differential Release Double Sided Paper |

| Peel Force Ratio | 1:1 (Identical on both sides) | Customized (e.g., 1:3 or 1:10) |

| Adhesive Migration Risk | High; adhesive may lift from both sides. | Low; adhesive stays on the tighter side. |

| Processing Suitability | Manual or slow-speed application. | High-speed rotary and flat-bed die-cutting. |

Material Science and Stability in Industrial Processing

The substrate of the double sided silicone release paper must be robust enough to withstand the mechanical pressure of die-cutting tools. Anhui Hengbo utilizes ISO9001 certified processes to ensure that every batch of PET release film maintains its dimensional stability under load.

Thermal Resistance in high temperature double sided silicone release liner

In industries like circuit board manufacturing, materials are often exposed to heat during lamination or curing. A high temperature double sided silicone release liner is designed to resist deformation and maintain stable release values even when exposed to temperatures exceeding 150°C. Standardized testing for thermal stability is governed by FINAT test methods, which have recently been updated to include more rigorous aging cycles for 2025.

Substrate Versatility: PET based double sided release film suppliers

Choosing between paper and film is a critical engineering decision. As leading PET based double sided release film suppliers, we recognize that PET substrates offer superior cleanliness and thickness tolerance compared to paper, making them ideal for "clean room" environments in the medical and electronic industries.

Precision Die-Cutting and Punching: The Professional Perspective

For B2B wholesalers, the goal is to minimize waste. During the die-cutting process, if the release paper fails, it can result in costly downtime. Utilizing wholesale silicone coated release paper for die cutting allows for the scalability required in high-volume production of gaskets, sealing materials, and reflective products.

Efficiency Benchmarks for wholesale silicone coated release paper for die cutting

Consistency is the benchmark of quality. A professional-grade release liner should exhibit less than a 10% variation in peel force across the entire web width. This ensures that the punching tools penetrate the material without snagging the adhesive or tearing the liner substrate.

Conclusion: Anhui Hengbo's Commitment to Material Excellence

The successful implementation of double sided silicone release paper depends on the harmony between silicone chemistry and substrate engineering. By utilizing differential release double sided silicone paper and high-quality high temperature double sided silicone release liner, manufacturers can eliminate adhesive migration and achieve precision in every cut. Anhui Hengbo New Material Co., Ltd. remains dedicated to providing thoughtful, integrity-based services and customized PET solutions to help our customers succeed in an ever-evolving market.

Frequently Asked Questions (FAQ)

- Why is "differential release" necessary? It ensures the adhesive stays on one side of the liner when the other side is removed, preventing messes and waste during assembly.

- Can I get a high temperature double sided silicone release liner for soldering processes? Yes, our PET-based liners are engineered to withstand high thermal loads common in electronic manufacturing.

- What is the advantage of sourcing from PET based double sided release film suppliers? PET provides a smoother surface than paper, leading to a more uniform adhesive coating and better optical clarity.

- Does Anhui Hengbo provide custom double sided release liners for adhesives? Absolutely. We specialize in tailoring release levels and substrates to meet the unique needs of each customer's adhesive system.

- How do I prevent "silicone transfer" to my product? We use premium, fully cured silicone systems that adhere strongly to the PET film, ensuring no residue is left on your adhesive products.