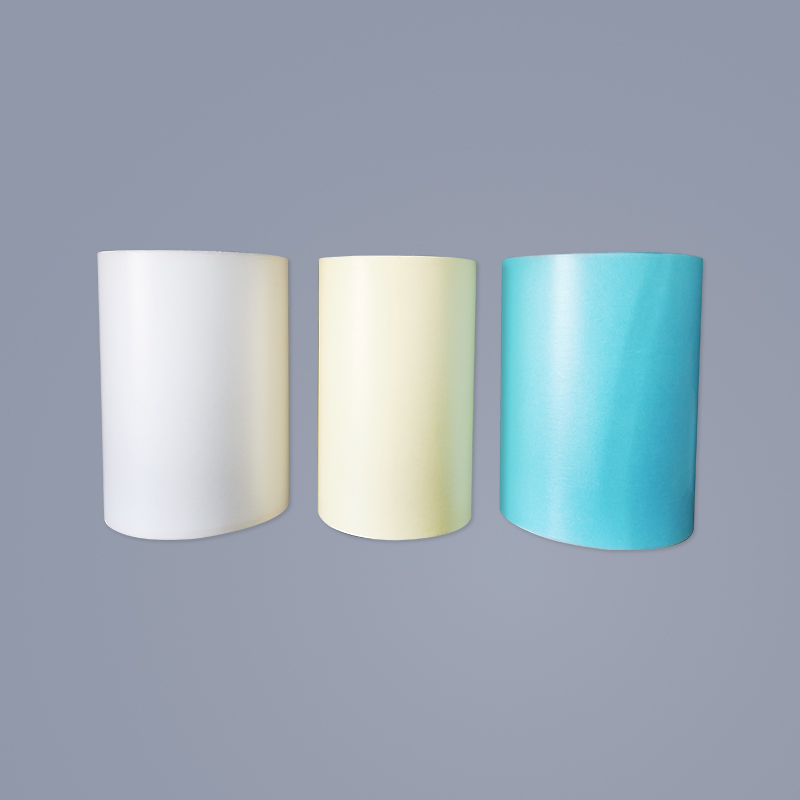

Anhui Hengbo new material Co., Ltd. is China Grain Release Paper Company and Wholesale Grain Release Paper Exporter. Products are mainly used for printing, silk screen printing, pad printing, nameplates, membrane switches, flexible circuits, insulating products, circuit boards, laser anti-counterfeiting, lamination, electronics, films for sealing materials, reflective materials, waterproof materials, medicine (plaster paper) ), toilet paper, adhesive products, die-cutting and punching processing and other industries. The company successfully passed the acceptance of safety production standardization and ISO9001 international standard certification. The company always adheres to providing more thoughtful services according to the needs of each customer, adheres to people-oriented, treats customers with integrity, and serves you on the principle of customer.

Grain release paper has high smoothness, good transparency, good stiffness, and uniform coating combined with silicone resin; Good fastness, good impermeability, good die-cutting performance, good dimensional stability, and good temperature resistance. Suitable for trademark label backing paper, especially for high-speed label pasting, double-sided tape, substrate packaging, etc. Mainly used in industries such as trademark barcodes, stickers, adhesive films, electronic die-cutting, anti-counterfeiting, adhesive tapes, and medical applications.

Contact us

Contact us