Product Features and Engineering Advantages

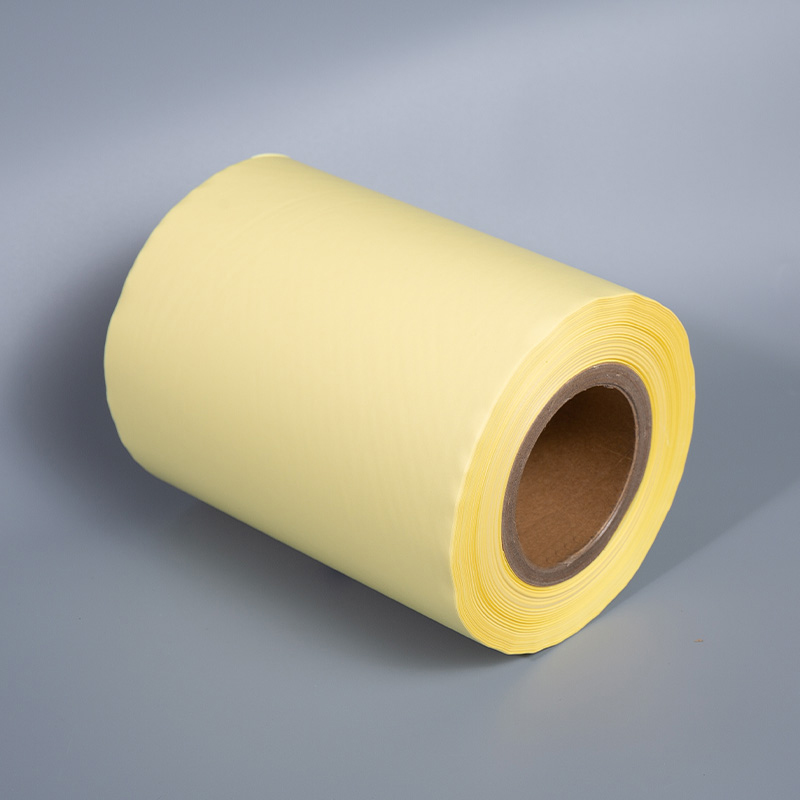

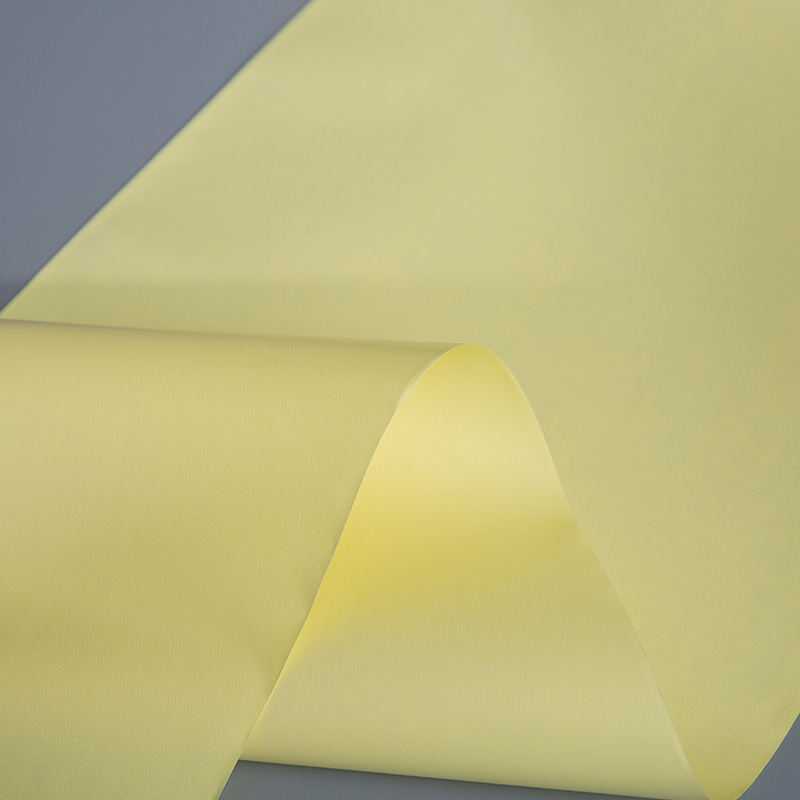

This release liner is optimized for demanding industrial processes. The copperplate base paper provides a smooth, uniform surface essential for the subsequent silicone coating application. The embedded yellow grid pattern release liner facilitates efficient alignment for automated machinery, directly contributing to waste reduction in high-volume adhesive manufacturing. Key advantages include:

- Controlled Release Profile: The proprietary silicone formulation ensures a consistent and specified release force, crucial for successful lamination and subsequent removal across various adhesive chemistries. This addresses the frequent B2B concern of silicone migration prevention.

- Dimensional Stability: The robust base paper exhibits minimal expansion and contraction under varying temperatures and humidity, maintaining roll integrity for precision die-cutting applications and complex converting processes.

- Visual Registration Aid: The distinct yellow grid provides immediate visual confirmation for positioning, which is particularly beneficial for manufacturing adhesive decals, medical patches, and complex flexible circuit boards where exact placement is mandatory.

- Substrate Compatibility: Suitable for use with both solvent-based and UV-cured acrylic and rubber-based adhesives, offering versatility for a range of pressure-sensitive material production.

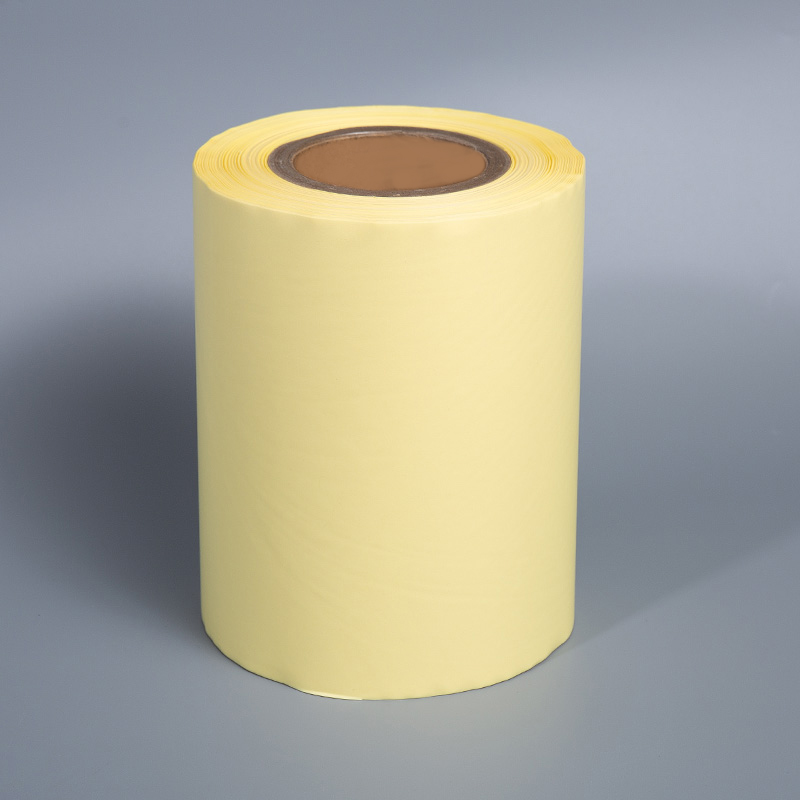

Technical Specifications

The following table outlines the key measurable parameters for the standard Yellow Grid Copperplate Release Paper Rolls, designed to assist procurement specialists in specifying release paper requirements.

| Property |

Test Method |

Standard Value (Nominal) |

Units |

| Base Paper Type |

Visual/Composition |

Clay-Coated Kraft (CCK) Copperplate |

- |

| Basis Weight |

TAPPI T 410 |

80 / 90 / 100 / 120 |

g/m² |

| Caliper (Thickness) |

TAPPI T 411 |

0.085 - 0.130 |

mm |

| Release Force (Light/Medium) |

FINAT FTM 3 |

10 - 50 |

gf/25mm |

| Silicone Chemistry |

Internal Standard |

Solvent-less Cured Silicone |

- |

| Grid Color/Spacing |

Visual/Measurement |

Yellow, 1cm x 1cm (Standard) |

- |

| Width Tolerance |

Measurement |

± 2.0 |

mm |

| Core Inner Diameter |

Measurement |

3 inch / 6 inch |

inches |

Targeted Industrial Applications

This specialty release paper is engineered to meet the stringent demands of multiple B2B sectors, ensuring optimal performance for industrial die-cutting release paper sourcing. Specific applications include:

- Adhesive Tapes and Films: Production of double-sided foam tapes, transfer adhesives, and specialty industrial tapes.

- Electronics: Used as a protective layer during the fabrication of membrane switches, flexible circuits, and heat-sink materials.

- Medical Sector: As a carrier for medical-grade adhesives, wound dressings, and transdermal patches.

- Printing and Labeling: Base material for manufacturing vinyl graphics, plotter films, and specialized high-tack self-adhesive labels.

Frequently Asked Questions (FAQ) for Copperplate Release Liners

What factors dictate the selection of a specific release force level for Yellow Grid Release Paper?

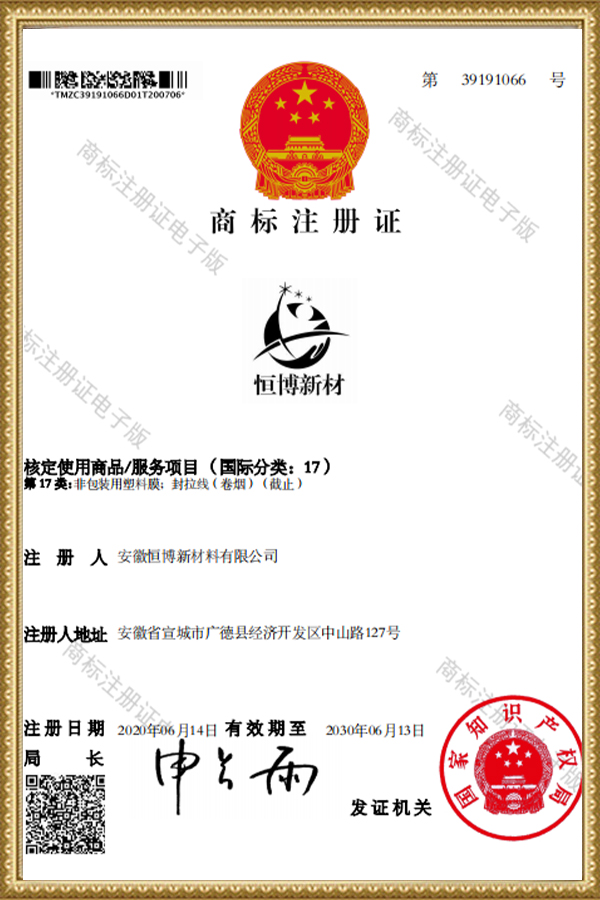

The requisite release force is a function of the adhesive type (e.g., acrylic, rubber, silicone), its coat weight, and the application's processing speed. A higher tack adhesive typically necessitates a heavier or 'tighter' release force to prevent premature delamination during rolling or storage. Conversely, a 'lighter' release is required for materials intended for manual peeling or delicate substrates. Anhui Hengbo New Material Co., Ltd. customizes the silicone coating formulation to achieve a range of specified release values, allowing customers producing items like die-cut components or insulating products to secure optimal adhesion and removal characteristics.

Can Anhui Hengbo New Material Co., Ltd. ensure the dimensional stability required for circuit board production?

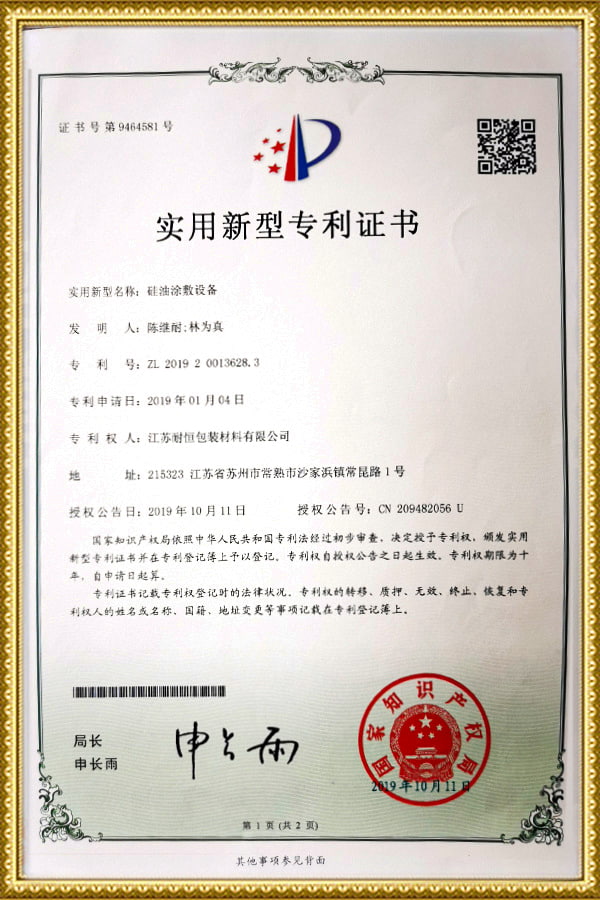

Yes. The stability of the base material is paramount for precision industries like circuit board manufacturing and flexible circuit production. The copperplate base paper employed is selected for its inherent dimensional stability and resistance to thermal distortion. Anhui Hengbo New Material Co., Ltd., established in 2017 and operating under IS09001 international standard certification, focuses on providing materials like this and PET release film that maintain critical tolerances throughout lamination, curing, and die-cutting. Our commitment is to offer products that serve as reliable functional carriers for complex applications, including laser anti-counterfeiting and nameplate fabrication.

What are the typical lead times and minimum order quantities (MOQ) for custom-width Yellow Grid Release Paper Rolls?

Lead times and MOQ are dependent on the required basis weight, specific release value, and the level of customization for roll width. Standard product configurations, often used for adhesive product conversion, generally have shorter lead times. Anhui Hengbo New Material Co., Ltd. adheres to a customer-centric principle, striving to provide more thoughtful services according to the needs of each customer. We encourage clients requiring non-standard widths for applications such as waterproof materials or die-cutting and punching processing to consult directly with our sales team to discuss feasible production schedules and MOQs. Our successful acceptance of safety production standardization confirms our capacity for reliable, large-volume B2B supply.

Contact us

Contact us