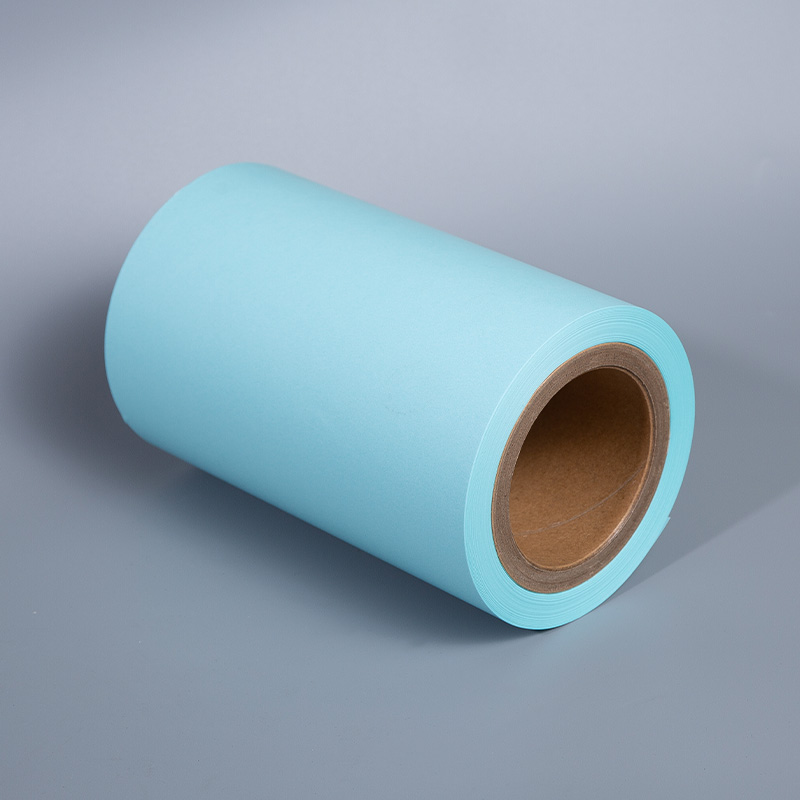

The Blue Grain Release Paper for Thermal Paper is a specialized release liner engineered for the manufacturing of self-adhesive thermal labels. This product utilizes a highly calendered glassine base, characterized by its dense internal structure and specific blue tint, which provides necessary optical contrast for electronic sensor detection in automated labeling machinery. The paper is treated with a precise solvent-less or solvent-based silicone coating, designed to deliver stable release values when laminated with various thermal paper facestocks.

Primary functionality focuses on dimensional stability and surface smoothness. The "grain" characteristic refers to the controlled surface topography that assists in silicone anchorage and prevents adhesive lock-up during prolonged storage. This substrate is developed to withstand the mechanical stress of high-speed rotary die-cutting processes, minimizing liner breaks and ensuring efficient waste matrix stripping.

Technical Characteristics and Performance

- Consistent Release Force: The silicone formulation is adjusted to provide a flat release profile, ensuring the thermal label separates smoothly from the liner across varying dispensing speeds. This minimizes the risk of label curling or pre-dispensing.

- Optical Density and Color: The specific blue coloration is calibrated to meet industry standards for opacity, facilitating accurate gap sensing in thermal printers and barcode scales.

- Mechanical Strength: High tensile strength in the Machine Direction (MD) supports tension control during the lamination and slitting phases. The paper's density allows for precise die-cutting depth control, protecting the liner from anvil damage.

- Chemical Resistance: The glassine base offers resistance to solvent penetration and plasticizer migration, preserving the integrity of the adhesive layer on the thermal paper.

Application Scenarios

This release liner is strictly positioned for the pressure-sensitive label industry. It serves as the carrier material for:

- Direct Thermal Labels: Used in logistics shipping labels (waybills) and retail weigh scale labels.

- Barcode Identification Systems: Variable information printing applications requiring consistent liner rigidity.

- Automated Application Lines: Scenarios where high-speed dispensing requires a liner with minimal caliper variation.

Technical Specifications

| Parameter |

Unit |

Standard Values |

| Basis Weight |

g/m² (GSM) |

58 / 60 / 62 (± 2.0) |

| Caliper (Thickness) |

µm |

50 - 55 (± 3) |

| Tensile Strength (MD) |

kN/m |

≥ 6.0 |

| Tensile Strength (CD) |

kN/m |

≥ 2.5 |

| Release Force (Tesa 7475) |

g/25mm |

10 - 15 (Light) / 20 - 30 (Medium) / Custom |

| Moisture Content |

% |

6.0 ± 1.0 |

| Color / Appearance |

Visual |

Blue / Grain Texture / Super Calendered |

| Residual Adhesion Rate |

% |

≥ 85 |

Frequently Asked Questions (FAQ)

Q: How does the grain texture affect the die-cutting process for thermal labels?

A: The grain texture on the release paper increases the surface area for silicone bonding and impacts the compressibility of the liner. A controlled grain structure enhances the liner's resistance to being cut through ("die strike"), which is critical for continuous processing. Anhui Hengbo New Material Co., Ltd., established in 2017, leverages precise manufacturing standards to ensure this texture supports die-cutting and punching processing industries. The company successfully passed the acceptance of safety production standardization, ensuring that the material properties remain consistent for manufacturers of adhesive products and nameplates.

Q: What are the storage requirements to maintain the release force stability?

A: Release paper should be stored in a controlled environment, typically between 20-25°C with a relative humidity of 50% ±5%. Extreme fluctuations can alter the paper's moisture content, leading to dimensional instability. Anhui Hengbo New Material Co., Ltd. advises strictly adhering to these protocols to preserve the ISO9001 international standard certification quality of the material. As a company engaged in PET release film and protective film for industries ranging from electronics to medicine (plaster paper), we adhere to providing thoughtful services regarding material handling to prevent issues such as silicone lock-up.

Q: Can this blue glassine liner be used with hot-melt adhesives?

A: Yes, the Blue Grain Release Paper is compatible with both hot-melt and water-based acrylic adhesives, provided the silicone system is matched correctly (e.g., solvent-free systems are often preferred for hot-melt). Anhui Hengbo New Material Co., Ltd. treats customers with integrity and serves on the principle of the customer, offering technical consultation to match the specific liner substrate to your adhesive type. Our experience in supplying films for sealing materials, waterproof materials, and circuit boards allows us to verify compatibility for complex lamination requirements.

Contact us

Contact us