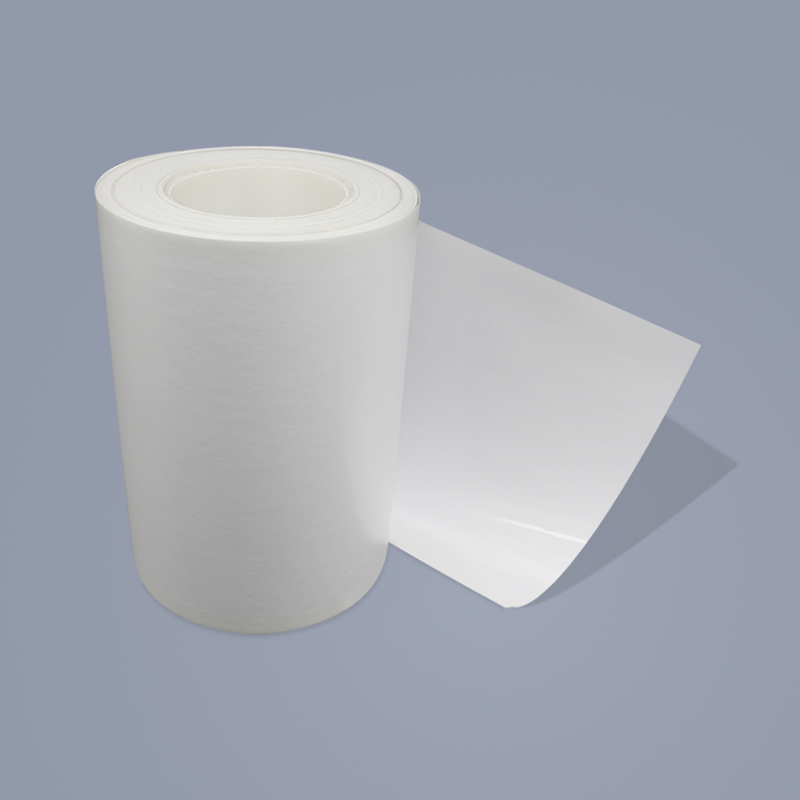

Key Technical Characteristics

- Mechanical Embossing Consistency: The depth and frequency of the grain pattern are calibrated to ensure uniform texture transfer across the entire web width.

- Thermal Resistance: The cellulose structure is densified to withstand curing temperatures typical in synthetic leather casting and composite prepreg manufacturing.

- Controlled Release Force: Available in differential release values to accommodate various tack levels of hot-melt and acrylic adhesives.

- Surface Tension Management: The silicone formulation is adjusted to prevent pre-curing adhesion while maintaining sufficient wettability for coating operations.

Applications and Usage Scenarios

The primary utility of White Grain Embossed Release Paper spans industries requiring surface texturing or specialized adhesive backing.

- Synthetic Leather Production: Acts as the casting paper for Polyurethane (PU) and Polyvinyl Chloride (PVC) leathers, transferring the grain pattern to the finished good.

- Composites Manufacturing: Used as a prepreg release liner for carbon fiber and fiberglass applications where specific surface friction is required during layup.

- Adhesive Tape Backing: providing a structured liner for double-sided tapes and die-cutting processing operations.

- Automotive Interiors: Manufacturing of textured dashboard skins and door panel materials.

Technical Specifications

| Parameter |

Unit |

Typical Value / Range |

Test Standard / Note |

| Base Paper Type |

- |

Super Calendered Kraft (Gracin) |

High Density |

| Basis Weight |

g/m² |

80 - 120 |

ISO 536 (Customizable) |

| Thickness |

µm |

75 - 110 |

ISO 534 |

| Release Force |

N/25mm |

0.10 - 2.00 |

FINAT FTM 10 (Adjustable) |

| Tensile Strength (MD) |

kN/m |

≥ 6.0 |

ISO 1924-2 |

| Tensile Strength (CD) |

kN/m |

≥ 3.5 |

ISO 1924-2 |

| Moisture Content |

% |

4.0 - 6.0 |

Equilibrium Relative Humidity |

| Temperature Resistance |

°C |

Up to 160 (Short Term) |

Suitable for oven curing |

| Residual Adhesion |

% |

≥ 90 |

SAS Check |

Frequently Asked Questions (FAQ)

Q1: How does the re-usability of embossed release paper compare in synthetic leather casting?

The re-usability of casting paper depends heavily on the thermal stress applied during the curing cycle and the chemical resistance of the silicone coating against the PU/PVC resin. High-density Gracin bases generally offer improved durability compared to standard kraft papers. Anhui Hengbo New Material Co., Ltd., established in 2017, focuses on manufacturing PET release films and protective films alongside paper substrates that meet rigorous industrial standards. While specific reuse cycles vary by production line, our adherence to ISO9001 international standard certification ensures that the structural integrity of the base material is maintained to support process efficiency.

Q2: What factors determine the shelf life of silicone-coated release papers?

Shelf life is primarily dictated by storage conditions (temperature and humidity) and the stability of the silicone chemistry. Exposure to high humidity can cause the paper fibers to swell, potentially altering the lay-flat characteristics and dimension. To mitigate this, proper packaging and climate control are essential. Anhui Hengbo New Material Co., Ltd. serves various industries including electronics, die-cutting, and medicine (plaster paper), and we emphasize safety production standardization. We treat customers with integrity, ensuring that our products, from insulating materials to release papers, are delivered with specifications that account for storage stability requirements.

Q3: Can the release force be customized for automated die-cutting processes?

Yes. Automated die-cutting and punching processing require precise release values to prevent "label drop" or web breaks during stripping. A release force that is too light may cause premature separation, while one that is too heavy can snap the matrix. Anhui Hengbo New Material Co., Ltd. provides thoughtful services tailored to these specific needs. Whether for membrane switches, flexible circuits, or adhesive products, we adjust the silicone formulation to achieve the exact release differential required for your equipment, adhering to our principle of being people-oriented and customer-centric.

Contact us

Contact us