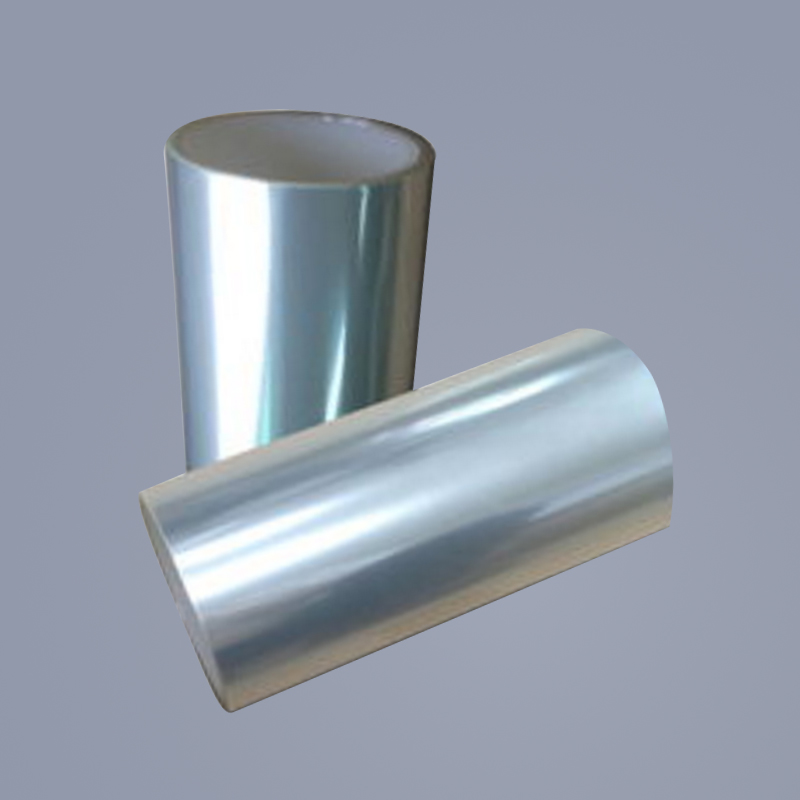

Product Characteristics

- Uniform Surface Smoothness: Provides a consistent, low-surface-energy plane that facilitates clean and complete release of adhesives and resins.

- High Light Transmittance: The transparent nature allows for visual inspection and alignment during lamination and die-cutting processes.

- Dimensional Stability: Exhibits minimal thermal expansion and contraction, ensuring registration accuracy in multi-step manufacturing.

- Chemical Resistance: Maintains integrity when exposed to a range of solvents and chemicals used in printing and coating operations.

Product Description

This smooth transparent PET release film is engineered to function as a stable and reliable carrier or protective interface in industrial composite and adhesive applications. Its primary technical principle relies on a controlled release coating applied to a polyethylene terephthalate substrate, which creates a predictable and non-transferring separation boundary. This design addresses the requirement for a durable carrier material in processes such as flexible circuit fabrication, membrane switch assembly, and the production of insulating materials.

The manufacturing process adheres to standardized protocols, and the product is produced in facilities that have successfully passed IS09001 international standard certification and safety production standardization acceptance. The technical advantage lies in the film's consistent performance, which contributes to reduced waste and improved process yield in precision die-cutting and lamination.

Technical Specifications

| Parameter |

Typical Value / Description |

Test Method / Standard |

| Base Material |

Polyethylene Terephthalate (PET) |

- |

| Total Thickness |

50 µm, 75 µm, 100 µm |

ASTM D374 |

| Release Force (from liner) |

Low (e.g., 5-15 g/in) or Medium (e.g., 20-60 g/in) |

PSTC-4 / FINAT FTM-10 |

| Tensile Strength (MD) |

> 150 MPa |

ASTM D882 |

| Elongation at Break |

> 120 % |

ASTM D882 |

| Thermal Stability |

Stable up to 150 °C for short durations |

- |

| Haze |

< 2 % |

ASTM D1003 |

Application Fields

This product is suitable for the following industrial scenarios:

- Carrier film for flexible printed circuits (FPC) and printed circuit boards (PCB)

- Release liner for pressure-sensitive adhesive (PSA) tapes and labels

- Protective interface for membrane switches and nameplate die-cutting

- Separation layer in the production of composite materials and insulating products

- Backing material for laser anti-counterfeiting films and reflective materials

- Process film for screen printing and pad printing operations

FAQ

What are the key factors in selecting a PET release film for a specific application?

The selection is primarily determined by the required release force, thermal resistance, and dimensional stability. The release force must be compatible with the adhesive to ensure clean separation without residue. Thermal resistance is critical for processes involving heat lamination or curing. Dimensional stability ensures precision in multi-layer registration. Anhui Hengbo New Material Co., Ltd., established in 2017, specializes in PET polyester and release films and provides technical support to help customers select the appropriate film specification based on their specific process parameters, such as those used in flexible circuits, membrane switches, and die-cutting operations.

How does the manufacturing and quality control of this film ensure consistency for industrial use?

Consistency is achieved through controlled raw material sourcing, a standardized coating process, and rigorous in-process and final inspection. Key parameters like thickness, release force, and surface smoothness are monitored against established specifications. Anhui Hengbo New Material Co., Ltd. operates with a quality management system certified to the IS09001 international standard, which provides a framework for consistent production and continuous improvement. This system, coupled with the company's commitment to serving customer needs, ensures that the PET release film delivers reliable performance in demanding industrial environments like electronics and adhesive product manufacturing.

Can this PET release film be customized for unique processing requirements?

Yes, variations in parameters such as thickness, surface treatment, and release force level can be engineered to meet specific application needs. Anhui Hengbo New Material Co., Ltd. is engaged in the development and production of PET films for a wide range of industries, including printing, electronics, and medical (plaster paper) applications. The company adheres to a principle of providing services according to the needs of each customer. For specialized requirements in areas like high-temperature lamination or unique die-cutting profiles, it is recommended to consult directly with their technical team to evaluate feasibility and develop a suitable product specification.

Contact us

Contact us